call Us

+91 98989 68864

E-mail us

smartechengineering27@gmail.com

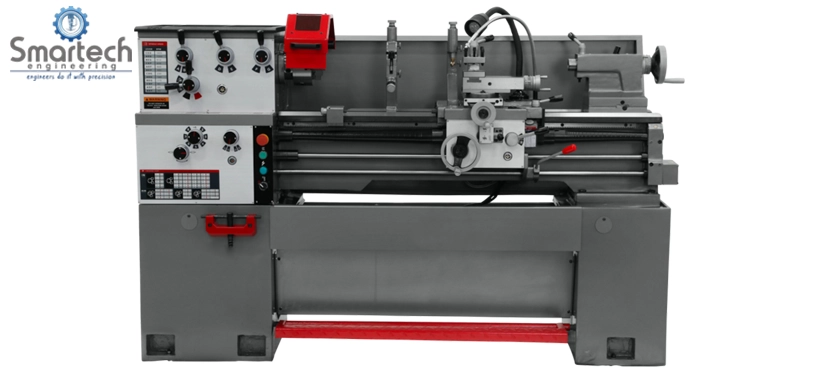

DRO & Lathe Machine

A DRO, or Digital Read Out, is a device used in machining and manufacturing processes, often in conjunction with a lathe machine. Here's an explanation of both:

Digital Read Out (DRO):

- A DRO is an electronic device that displays the position of the cutting tool or workpiece on a machine in numerical format. It provides precise measurements of the movements of the machine's axes.

- DROs are commonly used in milling machines, lathes, grinders, and other machining equipment to improve accuracy and efficiency.

- They typically consist of digital displays, encoders, and sensors that track the movement of the machine's components.

Lathe Machine:

- A lathe is a machine tool used in machining operations to perform various operations such as cutting, sanding, drilling, knurling, or deformation by rotating a workpiece against a cutting tool.

- It works by holding the workpiece on a spindle that rotates rapidly while a cutting tool is brought into contact with it to remove material and shape the workpiece.

- Lathes are used in metalworking, woodworking, glassworking, and other industries for manufacturing cylindrical components, such as shafts, bushings, pulleys, and more.

- They come in various sizes and configurations, including engine lathes, turret lathes, CNC lathes, and specialized lathes for specific applications.

In practical terms, integrating a DRO with a lathe machine allows operators to precisely monitor and control the movement of the cutting tool and workpiece, enhancing accuracy and productivity in machining operations. The DRO provides real-time feedback on the position of the lathe's axes, enabling operators to make precise adjustments and measurements as needed. This combination is particularly useful in applications where high precision and repeatability are required, such as in the production of precision parts for aerospace, automotive, and medical industries.

Get in touch

You will find yourself working in a truly collaborative environment, resulting in an incredible experience and the best end product.